|

|

In the October issue of Eurosoft's eNewsletters we're going to take an in-depth look at Nesting. Why nesting and why now? Because of the enormous importance nested based manufacturing has gained in the industry, the expertise we have gained over the last five+ years, the realization that there is a lot of confusion in the marketplace and – last but not least – the solutions we can offer.

|

The Confusion about Nesting

The manufacturing industry suffers at times from a lack of non-standardization of terminology. Unlike other segments of society (just think of the military) widely used terms in a given industry are not

regulated by some “protocol” like “Roger this” and “copy that”. By and large that is a good thing – new things can develop and then they get named, the lack of the “correct”, “official” term will never

hinder progress.

However, this can lead to confusion: think of the word “nesting”. Easy enough, right? That is multiple small objects squeezed into a larger one. What objects? Well, mostly – but not always –

multiple rectangular objects (the parts) of a certain thickness in a larger rectangular object typically called a sheet or a plate. So are all solutions that arrange these parts on the larger sheet

a “nest”? What if there are some non-rectangular ones?

|

3 Types of Nesting

1) True Shape Nesting

When the word “nesting” is used it should normally be understood as “true shape nesting”: a flat object of constant thickness but pretty much any shape:.

|

|

|

2 & 3) “Nesting” of Rectangles: 2 distinct flavors:

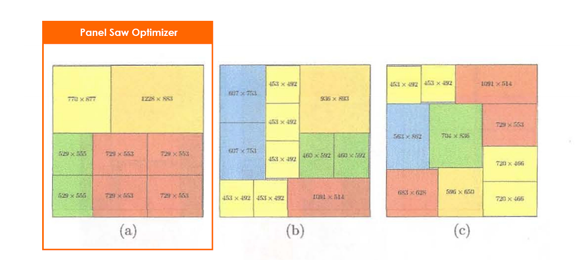

Panel Saw Optimization vs. Block Nesting:

The predominance of rectangles in the woodworking industry and many others has led to the development of special machines (panel saws, shears) that deal very efficiently with straight lines and rectangular

shapes. That in turn requires a special type of “nesting”: in the scientific literature it is called “2d guillotine cutting”. Many scientific publications deal with the topic every year, hundreds of

mathematical methods that differ from each other to varying degrees have been proposed.

What is special about "2d guillotine cutting"? Just like with the name sake device the cut has to go all the way through, “chop it off”, so to speak. Simply put, a saw blade cannot take a right or a left

turn. Stopping in the middle of the sheet and reversing course it not a valid option either. Obviously the requirement to “cut all the way through” imposes pretty severe limitations on the “nesting” or

“optimization” logic.

Block Nesting (called “2d non-guillotine cutting” in the scientific literature) on the other hand is not restricted by single-axis machine rules: the tool (think of a router bit or

scissors, etc.) can take a right or a left turn in the middle of the sheet of material.

|

|

Of the 3 “nests” shown only a) qualifies as 2d-guillotine pattern, b) and c) could not be cut on a single axis machine

|

Remarks:

• For more details see E. Bilkin et al, “Generating unconstrained two-dimensional non-guillotine cutting patterns by a _ recursive partitioning algorithm”, University of São Paulo, Brazil, April 2010

• See a simulation of cutting pattern a) on a panel saw: http://screencast.com/t/3DA2rrSZ

|

|

Which One is Better?

Obviously if shapes more complex than rectangles (or at least quasi rectangular shapes) are to be nested then there is no choice: True Shape Nesting is pretty much the only option available. A rare

exception to that rule can be found in shapes that can be easily surrounded by a rectangle or if the manufacturing process or the equipment available lend themselves to “cut rectangles first, then the

final shape from each rectangle”.

Then should True Shape Nesting software solutions be used for rectangles as well? After all, a rectangle is just a simple, regular shape!

The answer is NO, categorically so. True Shape Nesting programs are typically very bad at dealing with simple regular shapes – they spend a lot of time and

computing power “thinking” about what seems to be obvious and then come up with a noticeably flawed solution for rectangles. Obeying the stringent rules of guillotine cutting is out of the question.

Panel Saw Optimization and Block Nesting (or 2d-guillotine vs. 2d non-guillotine cutting) will many times produce very similar results – after all, it’s just about rectangles. Still, there are significant differences:

- Block Nesting rarely makes patterns that can be cut on a single-axis machine (panel saw or shear), if it does then it is by chance, not by design

- Panel saw optimization fails to take advantage of the freedom 2-axis movement offers but guillotine-type patterns will typically at least work on routers

- Sometimes one hears the argument that because of the straight lines a panel saw optimizer generates the cutting will go faster on a router as well. This is a specious argument because most cutting

on machines capable of movements in x and y takes place as single-part cutting, not “common line cutting” because of the inaccuracy of the tool diameter. Thus, the “straight lines” on the nest are

meaningless

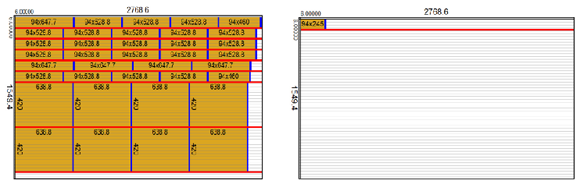

The new BlueCell Optimization solution offers both: 2d-guillotine cutting and non-guillotine cutting. See below a perfect illustration of the difference between Block Nesting and Panel Saw Optimization:

|

|

|

|

It takes 2 sheets when optimized with Panel Saw rules

|

|

|

|

|

|

See a Free Webinar!

Topic: Panel Processing in the 21st Century

Presenters: John Liedl from Eurosoft, Inc and Rene Fritz from Schelling/Ima

See a recording of the Webinar here:

Free Webcast

|

| We've joined forces with Schelling/Ima and the Woodworking Network for an educational Webinar. Topic:

Panel Processing in the 21st Century. The presenters are John Liedl, president of Eurosoft,

and Rene Fritz, sales manager at our Partner Schelling/Ima. John and Rene will talk about the changing technologies and production concepts currently occurring in the manufacturing

industry and what manufactuers can do to take advantage of these changes and strengthen their competitive edge. Please join us! |

|

|

Thank you for reading our newsletter. We hope you found it informative. Please do not hesitate to contact us if you have questions!

|

Need more info? Want to get in contact? We'd love to hear from you |

|

|

|

Eurosoft, Inc. - Providing Innovative software to the manufacturing sector for 20 years. Software that improves productivity, automates production and provides greater insight into manufacturing performance. From off-the-shelf solutions to personalized, multi-vendor projects, we've got your software solution! Contact us for more information on our products.

|

Having trouble viewing this email? View it as a webpage

To unsubscribe click here

|

|

|