|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This is the first one of a series of enewsletters we are planning to send to industry professionals like you. I know that we all get inundated with mailings – on paper and even more so by e-mail. Then why yet another newsletter by e-mail? For us at Eurosoft, Inc. it is of course part of our marketing effort: it gets the word out about what we do, what our capabilities are, and hopefully gets you interested in what we have to offer. However, we also hope that for you, and for the industry as a whole, our newsletter will introduce automation concepts and ideas and make a small contribution to overcome the fragmentation of the industry, the lack of integration, and the ‘turfs’ guarded by one vendor or another. To achieve these goals our newsletter will be educational, composed of facts, calculations, and real-life stories. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The 4th Industrial Revolution in Action |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

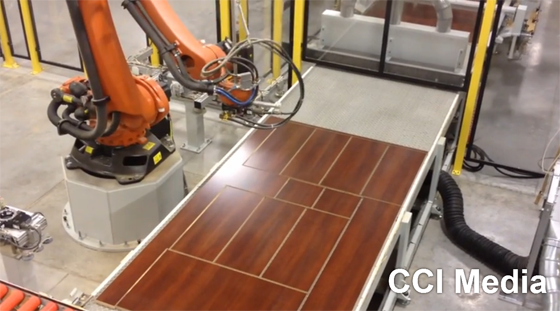

Indiana Furniture implemented a fully automated production line at their new plywood facility in late 2012/early 2013. A massive (12m x 45m) storage and retrieval system made by Dakota Automation is the starting point. The S&R feeds a nested based CMS router that cuts the parts. Once finished the out feed conveyor delivers the cutting pattern to an offload robot. That machine recognizes the position of the parts in the cut pattern, picks them up individually and places them on a conveyor system that delivers them through an RFID insertion machine to the final offload station. A second robot places the parts onto 5 stationary offload conveyors. Eurosoft, Inc. provided the integration software that receives the order from the ERP, processes them through a nesting logic and a post-processor to the router, and supplies the data to the S&R database. The database tracks which materials are needed in which sequence as well as the coordinates the first offload robot uses to pick up the parts after cutting. The post-processor for the router supports single parts cutting as well as common line cutting and incorporates tool path optimization. Another post-processor function is cutting scrap into pieces small enough to allow automated scrap removal via conveyor. Parametric G-Code templates and a formula parser make the post-processor extremely customizable: For instance, the tool selection automatically adjusts to the material type via an “IF” condition in the post-processor settings. Offloading of the parts after cutting posed numerous software challenges: exact position of the cut parts and their size are crucial factors in controlling the first offload robot (see link to video below). The sequence of the offloading plays a role in one of the most intricate software challenges Eurosoft dealt with: the final offloading onto the 5 stationary conveyors that has to follow certain logic to ensure stable stacks (Stacks must be built like a “Christmas tree” with the largest pieces at the bottom and smallest pieces at the top). “Book matching” (i.e. clusters of parts that need to be kept together for a visually perfect match) and handling remnants were also implemented successfully. The key component to the successful implementation of this automated production line was Indiana Furniture: Their project engineers combined vision with common sense, dedication to achieving their goals but with the flexibility required to reach them, high demands but with patience to see that the project was done right the first time. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FDMC Magazine will publish an article, with more information, about the same project in their March issue. Here is a link to a video clip of the system in action, courtesy of FDMC Magazine: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

I hope you have found this report worthwhile reading. Please do not hesitate to contact us if you have any questions. Next eNewsletter Topics: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||